Good bye oil, hello air source

Introduction

We moved to Dorset from Oxford in December 2020, and realised before we got here that if we wanted to live anywhere rural we would most likely have to say goodbye to gas supplies and get used to electric hobs and oil heating. Data shows that around 9.4% of homes in Dorset rely on oil heating, compared to some areas of Wales with over 35%. Something you don’t think about living in a city.

Since getting here we’ve adapted really quickly to an electric hob (actually, I like it better) but we really didn’t have any choice about ending up on oil heating. At an early stage in our move we were thinking about air source heating as a viable alternative.

We’ve not exactly been renewable-focused until now, although we’d signed up to Octopus Energy on 100% green energy as standard (more as a ‘least effort’ approach to being environmental).

Around 14% of UK greenhouse gas emissions come from gas boilers, and they will be banned in new build properties from 2023. The move to more sustainable heating methods is one that many people will be turning to, so we thought this story might be helpful to others looking to make the move.

Why we changed over

This is was our oil combi boiler. It smelled as bad as it looks. Situated in our garage it acted as an oil potpourri, ensuring every time we walked in to the garage we were reminded about being on oil heating with just one sniff.

The window with blinds you can see closest to the garage window is my study, which means if I had the window even slightly open I would get oil exhaust fumes to inhale while I worked. Nice.

We could probably have stood the smell if it actually did its job. But no, it couldn’t actually deliver suitably hot water. The result being we’d not had a bath in our new house since moving in , and washing up was always in lukewarm water.

Did I mention the huge plastic oil tank in the garden? It had its own fence to shield us all from looking at it, which works so long as you were not in the garden.

We were told that this needed filling twice a year (so that’s 2,000 litres), and that you need to dip it regularly to make sure you don’t run too low. It’s a far cry from just turning on the gas and never thinking about where it comes from.

About the house

It’s fair to say we had a head start with our house as a base for air source heating as it was only built in 2006 and so has benefited to a degree from improved building standards over older properties. So double glazing, cavity wall insulation etc are all standard. However, the house hadn’t really had any attention since it was built, so we were playing catch-up on stuff needing replacement/fixing.

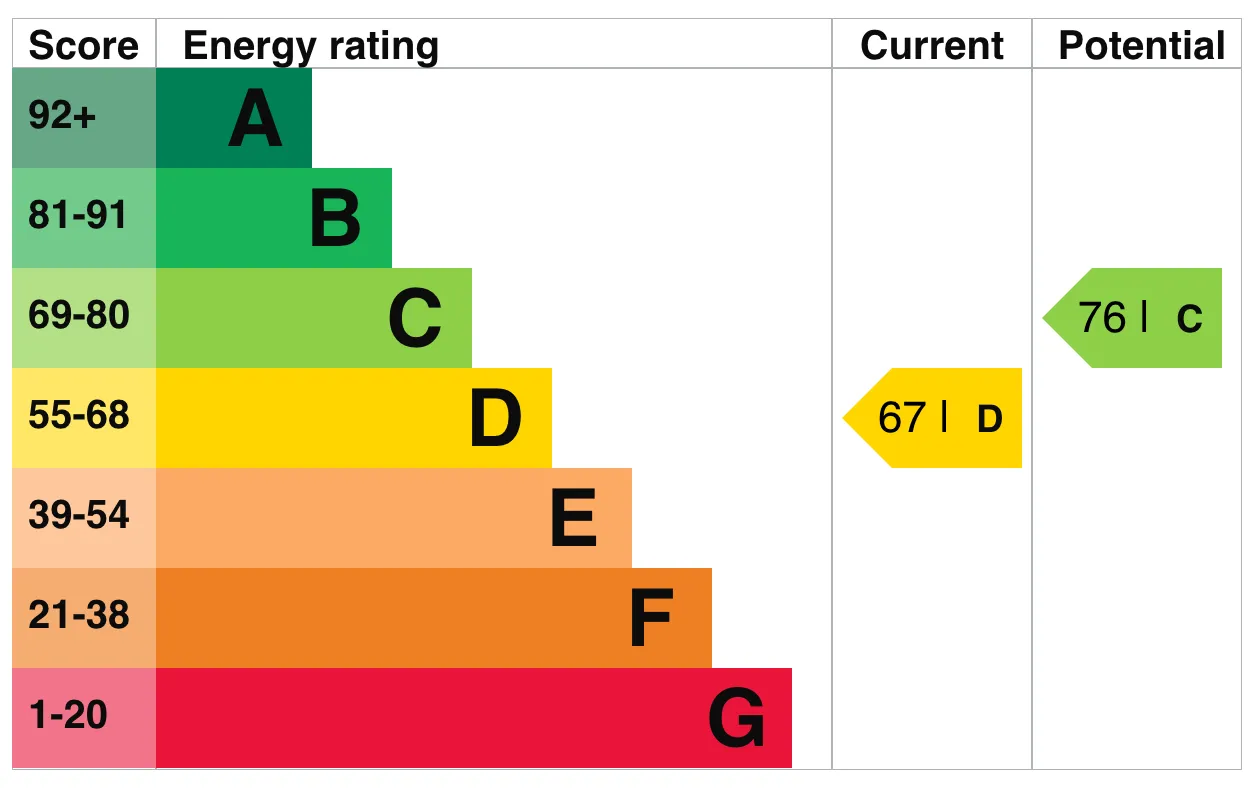

Its EPC rating was nothing to write home about, with most features of the housing getting a ‘Good’ rating. The worst aspects (getting an ‘Average’ rating) were the main heating and hot water, both of which were highlighted as areas to improve the overall rating to a C.

The deal with air source heating is that all the calculations are based on heat loss, so the better your home is at minimising this, the more efficient an air source solution will be.

How air source heating works

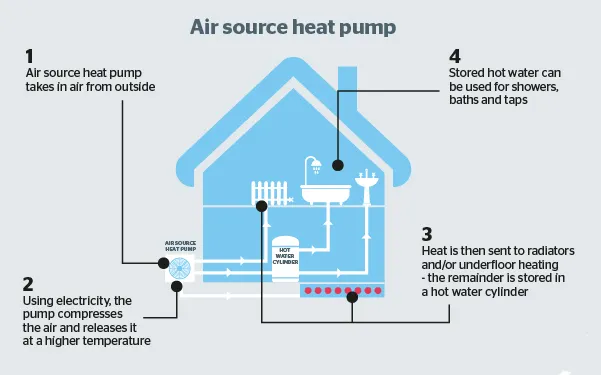

The science on this stuff still amazes me, but here goes…

Think of your fridge. It doesn’t ‘push’ out coldness, it sits there pulling heat out of anything you put in it. The secret is the refrigerant liquid zipping around at the back, which wants to turn into gas and does that through grabbing any heat energy it can (e.g. from your food) and evaporating. Ever felt the back of your fridge on the outside? Pretty warm, isn’t it?

The same principle applies with heat pumps, which are the driver of air source heating. Believe it or not, there is still energy in the outside air that can be ‘grabbed’ in the same way as a fridge — even down to -20 degrees C. 75% of the energy used for an air source heating system is obtained this way, with the remaining 25% from electricity.

Get ready for this: for every 1kWh of electricity used to power the heat pump system, between 3 and 4 kWh of heating energy are produced, giving the heat pump an efficiency of 300–400%, or higher. Woah!

The key elements of an air source system are:

- the fan unit; this is the outdoor bit that sits and pulls in air continuously to bring it into contact with the liquid refrigerant element right behind it. This turns it into gas as it grabs the heat, just like a fridge. Ok, so we’re off and running…

- the heat pump; this bit can be in the same unit as the fan (makes them bigger tho) or wall-mounted just inside (like ours, as we had the space). Essentially it takes the gas refrigerant and uses electricity to compress it which heats it up (check out the Gas Laws if you want to know the science). A heat exchanger then says “ooh nice, gimme some of that heat, you handsome refrigerant” and heats up water for the radiators and water tank. And back out goes the refrigerant to start the cycle again

- the water tank; I’m guessing you know what one of these is, but it’s the key to us having a bath, so it’s my favourite! Ours was to go in our garage rather than retrofit a load of piping to store it in our loft

- the bits that heat your home; so for us this was traditional radiators, but air source systems can also feed underfloor heating and air-to-air systems. Those are great for new build (air-to-air can also cool down houses in the summer) but too expensive for retrofitting to a house with an existing radiator system

There’s a nice overview from the Energy Saving Trust of how it all works, including costs and savings, which is worth a read if you’re thinking of going down this route

Finding out how to do it

I’ve made it sound like we did a batch of research before setting foot in this area, which would be misleading. We’ve learned as we’ve gone along.

We kicked things off looking for a supplier via the Green Deal Approved website. After looking around we settled on a local supplier; H2-Eco. They had a batch of awards and do a wide range of heating options so we got in touch, and we soon had the wonderful Dan assigned to us.

First steps were an intro visit/brief survey to get the measure of the house and create a ballpark quote. I think this is also to weed out those that are curious from those that might actually part with their money. But it was a good opportunity to answer basic questions around where to site the fan unit, where to put the water tank etc.

Next up came a detailed survey. This is to really refine the rough calculations made on the first survey and confirm:

- the space needed to be heated in the house, by room

- the expected heat loss given the state of the house and its insulation

- the energy needed to heat the space, taking into consideration the heat loss

From this you get two things:

- a recommended fan unit size (in kW) — the bigger your room space/worse your heat loss, the bigger the unit you need

- recommendations for adaptations to improve the system efficiency

Issues we needed to fix

These were the things that came out from our detailed survey:

- three of our radiators were too small to heat the space they are in. You can actually see this when comparing the radiator in our sitting room to its smaller cousin directly above in the main bedroom. So those needed to be changed out as part of the work.

- there was also an issue with the towel rail radiators in the bathrooms, which are more decorative than energy efficient, although they still push out some heat. We’re treating the bathrooms as ‘unheated spaces’ for the purposes of the calculations so we held on to them rather than change them for conventional radiators.

- the genius that built the house insulated the loft roof and not the loft floor, which means that our upstairs radiators spent a lot of energy heating the loft space, which was what our new system would need to do as well unless we changed things. How could anyone imagine it was a good idea going that way in the first place? Who needs a nice, warm loft?

Our badly insulated loft (not a NASA space capsule) with its haphazard boarding. Spotlight cones are just visible between the rafters

Our badly insulated loft (not a NASA space capsule) with its haphazard boarding. Spotlight cones are just visible between the rafters

- In addition, our house condition survey report wasn’t exactly glowing with praise about the loft insulation:

This type of insulation, was popular for a while during the 2000’s …. We are not aware of any Multifoil Insulation that is capable of meeting the requirements of Building Regulations for Thermal Resistance.

- we also have an open fire, which means a hole in the house open to the elements. You can get a chimney balloon to stop heat loss but they’re more for extended periods of blocking it up. In any case a) we love using the fire and b) what does Santa do then? We may have to come back to this one, I suspect

Also, not on H2-Eco’s list, but on ours:

- all the spotlight bulbs in the house (27 of them) were halogen so created a lot of heat as well as light. On it’s own this isn’t a big issue, but as we were looking to cover the loft floor with insulation, bulbs that generate heat could cause problems

The changes we agreed to meant that we could scale down from using an 11 kW fan unit to an 8 kW Daikin Altherma 3unit — a bit cheaper to buy and cheaper to run.

Green Homes Grant or Renewable Heat Incentive

I’m not going to go into the whole payback period thing as that wasn’t why we went into this. In any case, the financial advantage of switching heating system will depend on what you are on currently, as some methods are cheaper than others.

There are two ways to get financial help on switching to sustainable heating. Which one of these you go for is down to your particular circumstances, particularly how much you have in the bank to start with.

There’s been lots of excitement around the Green Homes Grant but the suppliers we spoke to had had issues with it; the Grant was announced before they were really ready to deal with applications, with the result that some suppliers just said they wouldn’t be dealing with them (not straight away, anyway).

Because it’s up to £5k (much more if you’re on benefits) this could cover 50% of the cost of a new system, so it’s attractive if you need a capital boost as an incentive. This has really driven up demand for sustainable heating solutions.

However, the fiddling around with vouchers and waiting around wasn’t for us — we just wanted our hot bath! So we went instead for the Domestic Renewable Heat Incentive (RHI) as this pays out a steady amount over 7 years. Our rough calculations show we might make more back on RHI than we would through the Grant.

Reading the latest on the Grant scheme makes me think we made the right choice. We have 12 months to make an application to Ofgem from the date of our installation to take advantage of the grant.

Getting ready for the install

Once we’d signed up and paid our deposit we had four weeks to get ready.

We started with our biggest issue; the loft insulation. It seemed pretty clear to us that we just needed to bite the bullet here and get the loft floor insulated to a recommended 270mm depth throughout. But as the loft space is also a great place to store things we decided we’d get part of it properly boarded too. As the photo above shows, it’s not exactly easy to store stuff in currently.

The depth of the insulation meant the current rafters weren’t high enough to accommodate it, provide air circulation and avoid compressing by the boarding. After a couple of inspections and quotes from local companies we decided on a firm called Loftforce as they do a nifty suspended flooring system (and sound like they fight crime in high places). This work was scheduled in for the week after our install.

Then it was time to get rid of those halogen bulbs. We found (head scratching time here) different rooms in the house use different spotlight fittings, seemingly completely at random. We found this out after we’d ordered all the replacement LED bulbs of one type, of course.

With the work due to cause disruption to heating, hot water, electrical supply and noise we decided to book some time working in the office we’ve never actually worked in due to COVID. We also booked a night away in a cheap hotel so we could wash ourselves (in warm water).

We were ready to go, just as the hot water decided to play more nicely…

The installation plan

Here is the plan we had from Dan in advance

Day 1

Heating and hot water off

Drain down the heating and remove the oil boiler

Place and mount all equipment; outdoor unit, indoor unit and cylinder

F-gas pipework, connections and testing

Start pipework in garage

Oil tank decommissioned by Yellowstone

Day 2

Pipework for the heating system in garage

Pipe up hot water cylinder and wire immersion heater (temporarily)

Hot water on

Day 3

Electrical work, supply to run in through loft to new garage board

Wire supplies to system equipment

Radiator changes

Fill up and pressurise and vent heating system

Day 4

Complete electrical works including control wiring and smart controller

Energise system

Heating and hot water on

Insulate pipework in garage

Remove all waste from site

Commission and hand over to customer

Installation week

Things kicked off on Monday with a call from Dan to ask if the parts could be dropped off ahead of Tuesday’s start date. Looking at this all sat in our garage waiting to be installed suddenly made everything feel a bit more real.

The outside fan unit (bigger than we’d thought) and the water tank (a perfect fit) sat in the garage ready to be installed

We were also over the moon at having made it through the coldest part of winter without having to refill the oil tank before the switch — that saved us some cash and also meant there was less oil to remove from the tank.

Talking of which, that oil tank was a bit of a handful to get out, and the colour of the remaining oil sludge that was pumped out even surprised the removal firm. In all probability this would have damaged the oil boiler if we had used it even for a few more weeks.

The new equipment was installed pretty quickly, with the heat pump working at the end of day 2 and starting to heat the water in the water tank. We had our first bowl of piping hot washing-up water on the morning of day 3, and our first bath too! Coming home from the office on day 3 we were greeted with the radiator work completed and heat in the house — a day ahead of schedule!

Some things didn’t go as planned, but in a good way:

- the oil tank removal was a day late but this allowed more progress with installing the heat pump

- H2-Eco realised that as our current radiators were in good condition we could play radiator switcheroo and re-use two of them in new locations rather than replace with new ones (also saving us some cash).

Continuing to work at home for the first two days of the install was a bit challenging without heat or hot water. It involved wearing lots of layers, hot water bottles and an endless supply of hot drinks. The drilling was also pretty loud (but sporadic) which made remote meetings…entertaining!

A new way of thinking about energy

Our handover from Dan was partly about how the system controls work but mostly about how we use these together to get what we want for the lowest use of energy. It became clear that we are just at the start of a journey, and one that requires us to think differently.

As the Energy Saving Trust put it:

Learn how to control the system so you can get the most out of it. You will probably need to set the heating to come on for longer hours, but you might be able to set the thermostat lower and still feel comfortable. Your installer should explain to you how to control the system so you can use it most effectively.

Firstly there’s the on/off nature of heating a house. When we had gas heating we’d set our thermostat to turn off when we were out of the house (remember when we all went to offices?) or at night as that was ‘saving energy’.

Air source heating starts from a different point; keeping the house at a constant, comfortable temperature. The cool down/warm up approach can take a chunk more energy than keeping it more level. As our oil-fired system had been so erratic we’d actually ended up doing this anyway.

Secondly there’s the relationship with outside temperatures. Air source heat pumps rely on extracting energy from the air, but when it is colder they have to work harder and use more electricity. Our system measures outside temperatures and uses a heating profile to minimise energy use, using less energy when the air is warmer. The profile settings can be adjusted to our hearts desire, but it’s going to take some time to get our heads around it.

One issue we’d raised with Dan was that our hot water was really hot, to the point we couldn’t get in the bath without loads of cold going in. We were shown how to set the heating profile for this too. Instead of mixing hot and cold water at the taps we’re able to set a lower average temperature for how water is heated and stored in the tank so we don’t heat it up beyond what is needed, saving us energy but still giving us those lovely, hot baths we’d been waiting for.

There are a batch of different sensors we can use to monitor the system, and an app to help us keep an eye on things, so it feels like we have lots more learning to do. But like checking food miles, or artificial additives, taking the time to think about how we use energy in a more responsible way feels like something everyone should be doing in a climate emergency.